In this article, we’ll be discussing a Tool Storage Assembly, and Head Tube Assembly Including the Tool Storage Assembly by Crank Brothers Inc., US publication 20210187713. The publication date is June 24th, 2021 and the filing date is Dec. 23rd, 2019. This has not been granted, yet.

CB = Crank Brothers, throughout.

Brief Summary (tl;dr)

CB are developing their own steerer integrated tool system. They make it pretty clear that they don’t like the OneUp system and are probably using it as inspiration. Imitation is the best form of flattery, right? This new system does not require any threading and does not sit inside the steerer, which takes space away from the tool. There are, technically, two tool units. One is the multitool and the other is a chainbreak, spoke tool, and CO2 inflator. There is also a container for your CO2 can or dime bag. The preload system sits under the stem and applies an upward force to the stem, after the stem is tightened. The attempted novel part is the way the tools and container attach to each other, where they use a ‘sliding connection 291/91/92’, rather than threads or whatever else is out there.

Background

We’re talking about integration, again. If you’ve been following along, this has been a hot topic lately, and with the recent patent filings, lots of companies are working on their own concepts. There’s a lot of empty space in a bike, why not use it?

Specialized, Lezyne, Granite, and Bontrager all have their own ideas out there. Honestly, you can probably pick any of them and they’ll all work great.

My wife and I are both running the OneUp system, and we love it. The fact that I always have most of the tools I’ll ever need to make adjustments, or fix something, is a huge deal for me. I also love that it’s such a clean look. But, there are some obvious drawbacks to their system, which is in the ‘why’ section.

Intended Novelty

This one isn’t granted, but it appears the explicit intended novelty is both the container and tool include a ‘sliding connection’ that engage each other. I expand on the sliding connection later on, but it’s the part noted below.

Why

CB call out OneUp, specifically. They don’t like the fact that you need to cut threads into the steerer, which voids the warranty (someone confirm that part). They also note that, due to the threads and the inner-steerer-mounted-top cap, you lose a small amount of space for the tool itself. I actually never thought of that and now I hate my OneUp tool. They also say the steerer will be weaker with the OneUp system, but I’m not sure about that. Seems like a stretch.

CB also mention the restrictions of certain fork materials (carbon), and the need for a special tool to adjust the headset preload. I’ll call bullshit on that one. A top cap/cassette tool isn’t special and you can tighten the preload with the actual OneUp tool.

I love the terse language from whoever wrote this. That star nut is just fucking jammed in there. lol

The most common system has a star nut jammed inside the fork steer tube, a screw tightened in the star nut, and a cap on top of the stem.

What

Let’s start with what everyone cares about, the multitool itself. FIG. 14 shows all the stuff you’ll [likely] get. This isn’t part of the actual novelty, so it could change through development, but it gives us a good idea of the tool. Seems pretty standard.

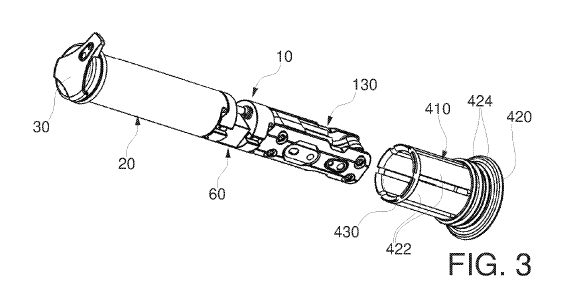

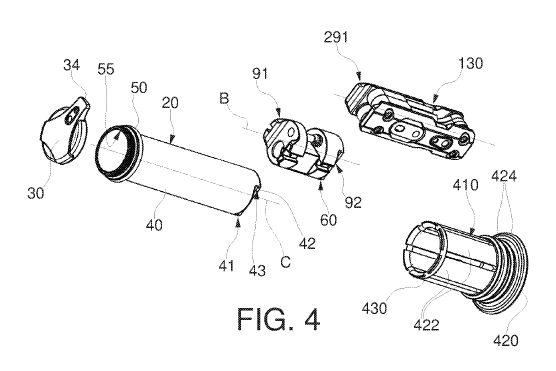

FIGs. 3 and 4 show this new tool system. All of the parts are attached to one another using sliding connectors, shown as 91, 92, 291, etc. That’s the novelty. Container assembly 20 will hold a CO2 canister or your dime bag.

Along with the multitool, you’ll also get a chainbreaker, spoke wrench, and a CO2 inflator in the second tool assembly 60. FIG. 11 shows all of these. 62 is the chainbreaker, 64 is the CO2 inflator pin, and 66 is the spoke wrench. You can see the sliding connectors much better in this figure.

FIGs. 15 and 16 show a super cool feature of the chainbreaker. It’ll actually slide onto the container body for ‘a comfortable, and strong, handle for leverage, since a significant torque is required to break a bicycle chain (to push a chain pin out of position)…’. I like that a lot. This part should fall under the claimed novelty, meaning you probably won’t see this on any other system.

FIGs. 25 and 26 show the headset tightening system. First, the steerer and stem are ‘pushed together by hand’ and the stem is tightened into place. Then, the headset tightener 310 is rotated to apply an upward force to the stem, removing any slack from the system.

So, how does this headset tightener work? FIG. 27 shows the assembly… assembled. FIG. 28 shows an exploded view. We’re focused on tightener 310 and threaded inner ring 330. Both of these parts are assembled and slid onto the steerer prior to installing the stem. The O-rings 450 apply friction to the steerer. Again, the whole system is pushed together by hand and the stem is tightened. Then, you’ll just turn the tightener 310 to apply pressure to the bottom of the stem. The O-rings should keep the inner ring from spinning. I imagine the O-rings will end up being very consumable. The screw 340 is then tightened to not allow the tightener to loosen.

Here’s an interesting line. CB may be thinking about putting this system into a pump:

Such solutions permit a user to store bicycle tools in a bicycle head tube assembly, or in another predetermined space provided in the bicycle frame, or even in a bicycle pump.

Conclusion

I know there’s a lot of people that’ll turn their noses up to constant integration, but I really like it. I like knowing I’ll always have a set of tools with me, in case some shit happens out in the middle of nowhere.

If this is anything like the rest of the Crank Bro’s products, this will probably be great quality. I’ll be honest, the preload system sounds a little suspect to me, but I won’t knock it until I try it. There’s a pseudo-rule in the aerospace industry, where if you can get one full thread to set, you’re good to go. Using that standard, I’d say getting 3-4 threads to set should be plenty strong enough to keep the system in place, along with the screw. That being said, you’ll definitely get dirt and dust in the exposed threads, though that should only be a problem when taking it apart, and you’ll hear that lovely crunch.

Either way, I’m a fan. I like the fact that it’s a bigger tool, holds a CO2 can, and doesn’t require any threads. I’ll be the first to say that when I was threading my steerer, I was shitting my pants. That’s not something I wanted to screw up.

“If this is anything like the rest of the Crank Bro’s products, this will probably be great quality.”

lol you must be new to the internet of mountain bikers and its absolute love (/s) of CB products.

Idk man, their pedals are pretty dope.

in case it wasn’t clear my comment was in jest. I have no beef with CB, but man do they get shit on by the internet for quality

From what I’ve gathered, threading the steerer would only void the warranty if it was the upper part of the steerer that failed. If your damper explodes after just 2 months, Fox or SRAM isn’t going to use a threaded steerer as a factor to approved or deny that claim.

Awesome. Great info!

Great idea using the crank-/hub-style preloader for this application, since preload backing off is a common complaint of the no-thread OneUp system. However…

“Such solutions permit a user to store bicycle tools in a bicycle head tube assembly, or in another predetermined space provided in the bicycle frame, or even in a bicycle pump.”

I mean, that’s literally exactly what OneUp did. Surely that can’t go towards the novelty.

That’s just general language to introduce the idea. Patent documents typically assume the reader knows nothing about any prior art, so they add shit like that.