In this article, we’ll be discussing a Suspension Fork Assembly by Hayes Bicycle Group Inc., US publication 20240208604. The publication date is June 27th, 2024 and the filing date is June 30th, 2023.

Follow along here

This is a new manufacturer for me. Not too many coming from Hayes and they typically have already released the thing to the wild. Unfortunately, this document is very matter-of-fact with little narrative, kind of like a Shimano document. I’ll extract what I can.

Brief Summary (tl;dr)

Hayes (Manitou presumably) are developing a new inverted carbon fork, likely for XC or gravel applications. The design doesn’t look too out-of-the-ordinary but the new concept here is the way the seal and wiper assembly is installed. The sealing components are included in what is called an ‘insert assembly’, which is adhered/glued into the carbon legs. They’re not bolted, screwed, threaded, or anything else; just glued in.

Background

While the Applicant says Hayes Bicycle Group, I think we can make a safe assumption this is coming from Manitou because Hayes owns Manitou, but I’ll call them Hayes throughout for continuity.

Manitou makes a version of an inverted fork called the Dorado, which is one of – if not the – most popular inverted forks in the MTB world. Because this article has nothing to do with the Dorado, I’ll let them talk. Here’s what Manitou say about their currently available inverted design:

Inverted Design provides an incredibly smooth and consistent feel due to constant lubrication of the bushings and seals. The inverted design also provides a major increase in fore-aft stiffness compared to traditional forks while maintaining torsional compliance which provides more control to the rider over rough terrain.

Another important feature of the Dorado is the use of carbon on their highest-end model – the Pro version. It appears as though Hayes/Manitou are continuing this concept with an inverted, carbon, short-travel fork.

Why

Matter.of.fact

It would be advantageous to provide an improved suspension fork assembly formed from a composite material such as carbon fiber…. providing a configuration for enhanced performance… enhanced mechanical Performance… enhanced aerodynamic Performance… improved piston assembly configuration.

Realistically, I think there are some real advantages to inverted forks that I have zero support to share with you. You can’t tell me moto hasn’t been using them for decades on accident. Everything is a compromise, and traditional telescoping forks likely have their advantages while an inverted fork likely has other advantages that lend itself to be more useful in different scenarios.

What

Exterior

FIGs. 2-3 show this new fork, including an extended and compressed state. Note the tapered steerer, adjustment mechs on top, and the tapered legs at the bottom. FIG. 4 shows an exploded view of this new guy.

Now here’s where this gets a little more interesting. FIG. 5 shows an exploded view of the upper part of the fork. Note the ‘CM’ nomenclature. This means each CM component is made of composite material and is explicitly defined as composite in the claims. So, the legs and steerer are very likely to be carbon.

This is where we’re getting into the intended novelty of the concept. We have this carbon leg, but we need to get bushings, rings, and seals into the leg, right? And we can’t just jam this stuff into a carbon leg, right? Hayes are saying their insert assembly 120 includes all of these components used to maintain fluid and air inside the fork legs.

An important part of the new concept here is the way the insert is assembled and/or attached to the legs. Label AD notes adhesive, meaning the insert assembly (containing all the seal-stuff) is glued into the legs. I understand this may sound suspect, but my understanding of the process of gluing carbon is pretty safe – just look at every lugged carbon-tubbed frame out there right now.

FIGs 10-12 show this insert assembly. We can see the insert 122, upper bushing 125, lower bushing 125, ring 126, and dust seal 128. This doesn’t appear to be out of the ordinary.

Going backward to FIGs. 8 and 9, we can see the insert installed in a leg.

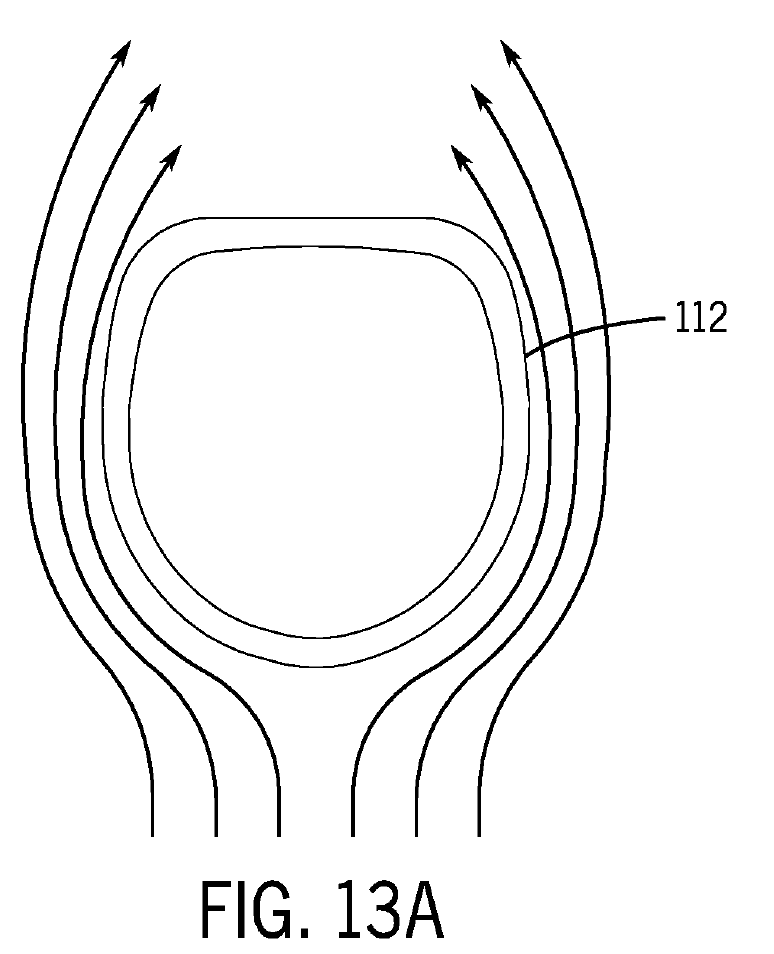

As mentioned prior, Hayes is looking to produce a more aerodynamic profile of a telescoping fork. FIG. 13 shows a cross-section of one of the legs in what they’re referring to as a Kamm Tail (Kammback). My Datsun has a Kammback design, for example. They mention the advantages compared to a circular profile.

…the aerodynamic profile may provide a drag force of less than 75 percent of drag force of a circular profile tube at 30 miles per hour (mph); the aerodynamic profile may provide a drag force of less than 1 Newton (N) at 30 mph.

Internals

I won’t go too deep into the fluid flow pathways because Hayes don’t state anything new or novel about it, but we can see the flow paths in FIGs. 15B and 15C in the piston assembly, each denoted with a P# arrow.

The table below corresponds with the flow paths given a certain state, needle, and load. It’s safe to say there are quite a few pathways, though again, not sure if anything here is new.

Even though this document doesn’t claim anything novel about this piston assembly, that doesn’t mean something isn’t new or we won’t see some continuation or divisional applications in the future.

For the suspension experts that read my ramblings, FIGs 16A and B show the piston assembly in both an assembled and exploded view. There are a shit load of shim stacks, compression piston 156, rebound piston 158, and the wave spring 155, among others. You guys would know better than I would if this is a decent assembly.

Tool

Let me jump back to FIG. 14 and roll it sideways because it’ll fuck up my wall of text if it’s upright. This is showing a cross-section of the damper side, which includes an IFP 180 inside the damper cartridge 141. How do we get that piston in the correct position? Because we need that dead-right in space.

FIGs. 17-20 show a fancy tool you’ll get with this fork. This new tool includes an INSTALL-side and a REMOVE-side, along with measurement marks. I’m sure we can all understand what this means. Note the collar 174, which provides a depth limit face when installing the piston. We can also see a hook system on the REMOVE side in FIG. 20.

FIG. 21A shows the piston and an important feature of its installation and removal. Note the round edge and a flat edge at the joggle (don’t have a better word than joggle). I’ll go into that next.

FIGs. 22A-C show a piston-installation-sequence. The piston is held in place on the install-side of the tool, then placed into the cartridge where the collar is set at the desired depth, and removed. Note how the tool pushes the piston up next to the flat edges of the piston joggle.

FIGs. 23A-24B show a removal sequence. The tool is designed to be inserted into the cartridge and then twisted around the round edges of the joggle so you can grab the piston and pull it out with that little hook I noted earlier.

Wonder if the removal could have just been done with a magnet? Make the piston neodymium and just pull it out?

How

I typically reserve the How section for manufacturing-related stuff. Rarely does anyone include that type of info, but Hayes has done just that in this document. Not only have they done this, but it’s super important to the intended novelty as the claims define a method of manufacture.

We talked about the insert assemblies being adhered with glue to the fork legs. FIGs. 26A and 26B show the fork in two scenarios, 26A being prepared and 26B is being cured.

In FIG. 26A, we can see the parts laid out in their proper configuration in a jig, and we can also see the adhesive AD again. In the prep-phase, each component gets some adhesive.

In FIG. 26B, the components are assembled and aligned with one another inside the jig, so each part is as correctly positioned as possible. It sets, and we’ve got ourselves a fork.

Intended Novelty

So, now that we know its components and it’s assembly, we can talk about wtf Hayes is actually trying to protect.

In no particular order, they define a composite (carbon) fork with a damper and spring leg. The damper and spring legs house a damper and spring assembly. Normal shit.

But now we get into the method of assembly, which includes prepping the insert assembly, applying adhesive to the insert assembly, jamming the insert assemblies into the legs, aligning at least two of the fork components in the fixture, and allowing the adhesive to cure.

Long story short, they’re trying to protect the assembly of their inserts in a carbon fork.

Conclusion

This thing looks really similar to the new Cane Creek Invert (shoutout Reed Mann). But, how different can a fork look from one another? I bet if you put a Fox and Rockshox fork in a phoropter, they’d look pretty similar, too.

I won’t sit here and try to explain the benefits of an inverted fork because I do not know. What I can tell you is when you see a convergence of an idea, that idea is generally going to be a correct answer. The convergence of inverted forks from companies like SRAM, Cane Creek, EXT, Intend, Push, and so on suggests this is a viable concept. Well, it should be a viable concept considering motos used it for, like, ever.

As far as the business case goes, there’s more questions than answers here. Is there enough appetite to switch to a fork like this? Are they aiming this concept at people who already have short travel forks and understand the value? Or are they aiming this at people like me with a rigid gravel bike? Is this straight-up going to replace a fork in their line-up? From my perspective, the unique part of the selling feature here is the use of carbon, and likely being super lightweight. Cyclists will eat that shit up.

I feel I need to insert some technical question in this, primarily because I have a fun story for you folks. I wonder if they’ve considered their coefficient of thermal expansion when adhering the inserts to the carbon, or if there’s enough heat to even matter. Because they’re likely different materials, they’ll have slightly different coefficients of thermal expansion (CTE), and varying levels of expansion can cause delamination between parts. This really depends on factors like final color and if the fluid, seals, or whatever can dissipate heat effectively.

I say this because this is something we played with in NASCAR for a bit. If you watched NASCAR in the 2014-2015 era, you may remember the side skirt games all the teams played. I did a lot of work on this feature, how it works, how to get it to the track, etc. The mode of success for this modification is an excessive evacuation of flow under the car due to low pressure behind the skirt. We could see these lower pressures under the entire car and even developed a good amount of front downforce due to the acceleration of flow under the splitter and radiator pan.

I bring this up because, at one point, we were toying with a way to get this flare-out without actually touching the car. The standard practice was to either have the pit-guys pull on the skirt or slam it into the ground to get it to flare out. But what if we could get it to flare without touching it?

The idea was to develop a two-part skirt, where each part had a drastically different coefficient of thermal expansion. As the exhaust (black below) heats the materials (blue and red), the difference in CTE would result in a bent skirt section. It’s been many years and my brain is basically mush, but if I remember correctly, delamination was a concern. It didn’t affect us too much because the skirts were bolted at the top anyway. It seemed to work decently well – well enough to make performance – but was never implemented due to bending the rules too much. Looking back, I have to agree. That was a bit much.

Anyway, that was way off topic but an interesting anecdote if you’re interested in NASCAR trickery. This was nothing more than an extreme example of thermal expansion in a practical application, but I’m confident Hayes shouldn’t have a problem with it.

Leave a Reply