In this article, we’ll be discussing an Inflation System for Tubeless Tires by Santa Cruz, US patent 10,926,591. The publication date is Feb 23rd, 2021 and the filing date is April 17th, 2020. This patent has been granted as novel.

This is the first Santa Cruz patent I’ve seen while doing this, so I have to write about it. For those that don’t know, Santa Cruz is about as American as Budweiser. They’re owned by Pon Holdings, a Dutch conglomerate. It’s interesting that this idea isn’t actually assigned to Pon; it’s assigned to Santa Cruz themselves. Almost all other Santa Cruz ideas seem to be assigned to Pon.

Reserve Wheels are the wheel manufacturer for Santa Cruz, so this idea is probably coming from them, not Santa Cruz themselves. I’m going to refer to Santa Cruz throughout (because that’s the assignee), but it’s probably not theirs.

Way late edit: This is the Reserve Fillmore Valve.

Brief Summary (tl;dr)

Santa Cruz (or Reserve wheels, whoever) are introducing a new tubeless valve system, with a new valve, a refillable sealant canister, and a pump head to fill the canister. The inside of the valve will allow for better air and sealant flow to the tire, reduce valve clogging from the sealant, and improve bead seating. The canister can be filled with sealant and pressurized. Then, the rider can inject sealant into the tire like a heroin addict – without deflating the tire (very important). Lastly, the pump head is specially designed to fill the canister. But, you’ll love this, there are no necessary required proprietary pieces (confirmed by SC), but you can use the proprietary system if you want to — which probably works best. Santa Cruz are offering Presta and Schrader valve core adapters for this system, and they’re also saying the sealant canister can be pressurized with a bike pump. What a fucking huge win of a design.

Background

There are two major designs for bike tire valves: Schrader and Presta. The Schrader valve we know today was originally patented all the way back in the early 1890’s. It’s a design that’s stood the test of time and, from what I can find, hasn’t had much adjustment since the original design. Schrader valves are the valve of choice in the automotive world, nearly exclusively. They’re even used on our suspension systems, refrigeration systems, and fire extinguishers. They just work.

The Presta valve appears to have been designed for a bike (though there are probably other applications). From what I can find, the design intent was to solve the problem of a big ass hole in your bike rim, where the rim would then be the weakest. The smaller the hole, the stronger the wheel. This allows designers to maintain narrower rim profiles compared to wheels with Schrader valves.

Intro

I’ll start with what everyone is thinking; is this a new standard? I actually got some information from Santa Cruz themselves (we out here boys), and I can confirm that you will not be required to buy into a new standard, and it will not require a new hole size in the rim itself. That’s all I could get out of them. Now that your anger is gone, let’s move on.

Santa Cruz are introducing a new type of valve system for a tubeless tire system, and a method to add sealant to a tire. This appears to be a wholesale change to the entire valving, sealant, and inflation system that we’ve all come to despise (at least I do).

So, there are three components here: a valve, a sealant canister, and a pump head. The valve itself is going to work very similarly to the current Presta system, where there’s a stem inside a valve body, but the stem is very long and reaches each end of the valve body, rather than a portion of the interior of the valve body like the Presta system. There’s also an interesting cap design, which we’ll go into later.

The sealant canister can be filled with sealant, then pressurized. When the canister is attached to the valve, the sealant is injected into the tire at full gas. The important part here is that you can put sealant in your tire without deflating your tire.

Lastly, the pump head. This appears to be similar to a chuck valve system, which can be properly attached to your sealant canister to apply pressurized air. This part is probably optional and I go deeper into that later on.

Intended Novelty

It appears as though the explicit intended novelty here is the actual process of releasing air, as strange as that sounds. Typically with a Presta valve, for example, you unscrew the cap, press down on the valve core, and release air. Santa Cruz’s system allows for backing out the valve cap, without removing it, and pressing on the valve cap to release air. I know, legal shit is weird, but it’s novel according to the USPTO.

Another novelty appears to be the fact that the valve seat is larger than the inner diameter of the valve body, so it can seat easily. Lastly, the fact that the valve stem is slotted and is retained by a pin may be claimed as novel, hard to tell on that one.

Why

This is an excellent patent to read, because I can give you some information that isn’t typically included in other documents. Santa Cruz are very clear about their intentions and reasoning behind the design itself. It’s a breath of fresh air for me, and hopefully to the people that have gotten this far in the article.

Santa Cruz state this new design relates to improved air flow, easy sealant application, bead seating, and a reduction in valve obstructions due to sealant in the valve itself.

Many tubeless tires use either Presta valves or Schrader valves to facilitate inflating the tire. However, these valves typically provide insufficient air flow for initial seating of the tire to the rim, do not allow for easy addition of sealant, and are often clogged by sealant due to their small diameter

Santa Cruz state the process of removing the valve core to refill the sealant in a tire is not ideal.

Some existing tubeless tire valves allow for the addition of sealant by providing a valve core removal tool. However, these valves require complete deflation of the tire for sealant addition and are built within a Presta or Schrader valve body, resulting in the same air flow and clogging problems as typical Presta or Schrader valves.

They offer a little more detail on the current Presta/Schrader valve, and why they suck.

High flow hand pumps and compressed air canisters are typically used to seat a tubeless tire to a bicycle rim. High flow pumps include a large internal pump piston, providing higher flow than a standard hand pump. Compressed air canisters hold a large volume of compressed air, providing a constant stream of high flow air. However, Presta and Schrader valves restrict air flow due to their small internal diameters.

Santa Cruz want to be able to inject sealant with a tire at pressure. That’s a big change.

…[other methods] are unable to inject sealant into a tire under pressure, with the valve intact.

They also don’t like clamp-on or press-on pump heads.

Clamp-on pump heads also require more hand strength to operate, resulting in increased stress on the bicycle valve and bicycle rim… Press-on pump heads clamp and seal to the bicycle valve using an O-ring. O-rings often do not provide a large enough clamping force for higher air pressures.

So, there are many many reasons for this design.

What

There are multiple different designs for the valve in this document. I’ll only talk about the first one, which is the example this particular patent is protecting. All others are very similar, but it’s just too much information for a single article. Check out the link at the top if you want to dig into the others.

.Alright, lets start with the valve. Figure 1 shows a cross-section of a wheel and the valve in place. There’s nothing really spectacular as far as implementation of the valve. It’s similar to what we’re already used to.

Santa Cruz have a statement on the reasoning behind this specific design:

[the system has a ] larger internal diameter than typical bicycle valves ( e.g., Presta valves or Schrader valves). This results in a higher air flow and reduced clogging, while the valve body still fits in a rim hole drilled for a Presta valve. Higher air flow makes seating a tire to a bicycle rim easier, improves pumping speed, and allows for the injection of sealant into the tire without the removal of a valve core. Higher air flow also eliminates the need for compressed air. The larger internal diameter also allows for rapid tire deflation.

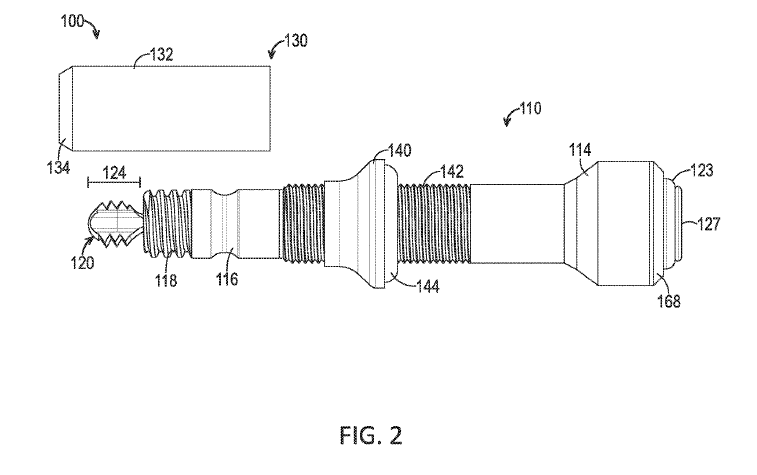

Figures 2 and 3 show the valve in the open and closed positions, respectively. Note how the valve stem 120 is threaded. We’ll get into that next. As you press the valve core in, the opposite end allows air to flow through the valve. Just as expected, though this is different than a Presta or Schrader valve core system.

Figure 4 shows a cross-section of the valve itself in the closed position. Notice how the valve cap actually threads into the stem, unlike the Presta system, where the cap threads to the core. When the cap is threaded into place, it applies a pulling force to keep the stem in the closed position. The pin 162 keeps the valve stem in line.

Figure 5 shows a cross-section of the valve in an intermediate position, where the valve is closed but the cap is unscrewed a little bit from the body. In this position, the valve stem is free to move but will stay seated due to the pressure in the tire.

Figure 6 shows a cross-section of the valve in an open position. The cap is still unscrewed a little bit, but when you press on the valve cap, the stem opens and releases air from the tire. This should be a cool feature if you want to let just a little bit of air out, rather than slamming a Presta valve fully open.

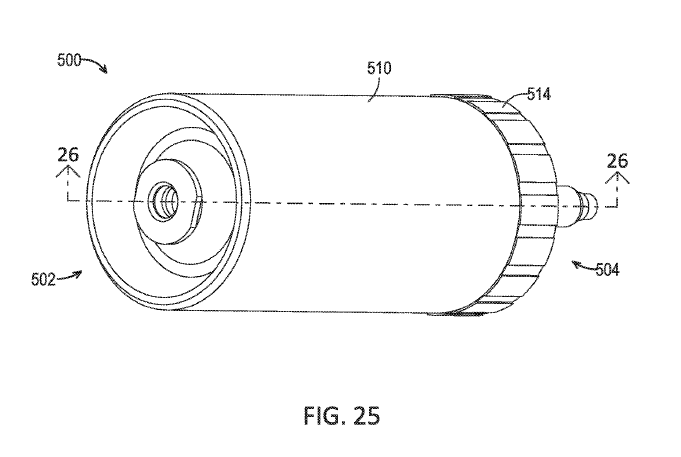

Figures 25 and 26 show the refillable sealant canister. It appears as though the cap 514 can be removed so you can fill the canister with sealant. When you’ve got it closed up, you can pressurize the canister using valve 550. Then, the canister is placed on the valve to both re-seal and re-inflate at the same time. I have reservations about the volume of air being injected, but the sealant part makes sense.

Santa Cruz state the advantage of this design:

This configuration allows sealant to be injected into a bicycle tire while the tire is pressurized, and allows for simultaneous tire inflation and sealant addition.

Santa Cruz have an important line about the canister valve. They state that the valve system shown in the figures is not required, and this can be any other type of valve. This opens the door for a user to not have to use the proprietary pump head, and you could use a regular pump they already own. Very smart move by them:

…canister valve 550 is a check valve, ball valve, and/or any suitable valve for fluid containers… Canister valve 550 is configured to be coupled to a head of a bicycle pump, which pressurizes the sealant canister.

Figures 30 and 31 show the pump head. This appears to be the optional part of the system, since we already know the canister can be filled with a bike pump. I would assume the pump head would be great for shop folk, that may need to do this a shit load of times every day.

The body 610 is attached to a hose via threads 614. The valve 550 of the canister is inserted into the collar/quick connect, and you just fill the canister. Pretty simple stuff.

Santa Cruz state the advantage of this pump head/canister system:

…examples described herein allow for the connection of a valve and pump head using a quick connect interface. This interface does not require twisting or jerking of the tire valve, preventing rim damage, de-seating of the valve, and tire deflation.

This is an important part for those that don’t want proprietary stuff. Figures 33-36 show valve core adapters. Santa Cruz have multiple valve core adapters that’ll fit Schrader and Presta systems so you don’t have to buy a whole new system (unless you want to). Though remember, if you use an adapter, you’re still using a Presta or Schrader, so you won’t have the advantages like seating and reduced sealant clogging.

Figures 33 and 34 show a valve core adapter for a Presta valve and figures 35 and 36 show a valve core adapter for a Schrader valve.

Finally, figure 38 shows the entire system hooked up.

Conclusion

Santa Cruz have developed an answer to a problem most of us just live with, and I commend them for that. I cannot tell you how many valves I’ve clogged with sealant – so frustrating – and how many times I’ve had to go down to the gas station to use their compressed air for seating a bead (I know, I need to buy a tank). The fact that they’ve addressed both sealant and seating issues in a single concept is impressive.

To many of you, this will be a minor improvement, but the fact that they’ve created a new valve system without required new standards is a huge win as far as engineering and marketing are concerned. That being said, they’ll probably offer this system in a proprietary manor, you just don’t have to use it that way – but it’ll work better that way.

Let’s be real here, this is Santa Cruz we’re talking about. I fully expect these valves to be on the high end of market pricing. But ol’ Bill from accounts receivable just got his $1400 stimmy, and this dude needs to have these on his new Megatower – there’s no other option, Stan’s are old news now. And this dude is going to be the bell of the ball out on the trails. These things will fly off the shelf so fucking fast, no matter the price. And I’ll be honest, I want them now too…

Interesting that these are out now, no mention of the sealant filling apparatus or, what is most exciting to me, the quick-coupling style connector.

Little bit worried that the production valves have a stainless central pin and an aluminium cap screwed onto it, seems like a recipe for some nasty electro galvanic corrosion down the line.

I also have my doubts about how well these will work with things like CushCore. Probably fine with their inflation gizmo, but how hard will it be to force the valve core up against the tyre insert to squirt in sealant through the valve without it?

Personally I don’t have a lot of issues with Presta but I’d definitely consider the Presta to Fillmore adaptors if it would let me use a pump with a nice pneumatic style quick connect.

I agree, I’m pretty excited to see the sealant system. Didn’t even think about the possible corrosion, hope they got that figured out. And I’ve gotten a few messages from people already using it and they’re saying it works fine with CC, no issues yet. Thanks for reading, George!